The water cooled oil cooler is the new generation of the air coolers.

We would like to introduce a water cooled oil cooler for racing with Maruhafs original design.

What is the difference between the usual air cooled oil coolers and Maruhafs water cooled oil cooler?

Most of the oil coolers sold on the market used to be air cooled ones.

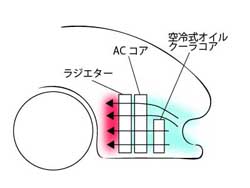

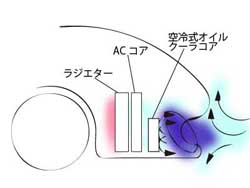

An A5`A4 sized air cooled oil cooler core is built in in front of the radiator.

The features of air cooled and water cooled oil coolers are as follows:

You can see that the original setup of the water cooled oil cooler is difficult. However, it's got lots of merits and for this reason it is being used in these daysf racing engines too.

Let us explain you more about each part.

The area of Miatafs (Mx-5) front bumper grillefs opening is not too big.

In the back part of the grille the air conditioner condenser and the radiator are set up in a double way.

To that we set the air cooled oil cooler core and we cover it with air resistance. This creates a severe situation.

Air can flow through the core of the air cooled oil cooler, A/C condenser and the radiator.

This construction allows the air to flow through them one after another, but does it flow through completely? The answer is efNOff.

The core becomes the airfs resistance and so the air that cannot enter into the core, flows by.

Also, it hits the oil cooler of the front row inside the small grille and cannot continue its way, thatfs why the reflected air creates a piled-up air space.

We talk about the air that is pressed against the piled-up layer, the air that flows by and the air that cannot enter the grille.

If we think about these facts, we might want to set up the cooler core outside the grille. However, if we donft use a special aero bumper, the setup might be difficult.

The point which Maruha considered the most is the following: To make the A/C condenser and the radiator function properly, we donft use an air cooled oil cooler but the water cooled oil cooler.

Let us explain about the water cooled oil cooler once more.

The water cooled oil coolerfs basis is: water temperature + 10 degrees = oil temperature.

The cooling happens using the waterfs temperature, thatfs why the oil temperature doesnft fall under this level.

It is important to verify if this oil temperature is the suitable temperature.

The water cooled oil coolerfs basis is: water temperature + 10 degrees = oil temperature. In other words, the oil temperature should be set to around 90-100 degrees.

On the contrary, in winter it is being heated by the water temperature, thatfs why it should be called HEAT EXCHANGER.

It has the function of cooling the engine oil and in other cases it has the function of heating it.

This means that the oil temperature must be constantly controlled. The engine's efficiency can be stabilized by this control. In the cases of racing engines air cooled oil coolers are not being used anymore.

An appropriate water temperature and oil temperature control is necessary to reach stabilized combustion needed for the engine.

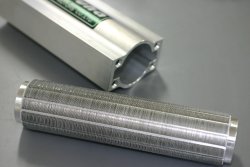

The cooler itself consists of housing and core.

The core is a tube, the outside of the central main waterway is covered with a small honeycomb waterway and in this way it becomes a doubled construction.

Compared to the standard water cooled core its efficiency is 5 times better and we have already obtained the patent.

Water and oil cannot be mixed, but they enlarge the aluminumfs surface and they raise the heat transfer efficiency.

Below you can see the makerfs official cooler efficiency chart of Maruha's core.

SIDE 1EEEoil flow / minute SIDE 2EEEwater volume / minute INLET (water temperature at the entrance) SIDE1EEEoil SIDE2EEEwater OUTLET (water temperature at the exit) SIDE1EEEoil SIDE2EEEwater

The general circulating water amount of the 4 cylinders is 40`60L. In this test we set the oil temperature to 120 degrees and the coolant temperature to 85 degrees.

As you can see, after cooling the oil temperature changes, it is in the range of 98`113 degrees. When achieving around 20`7 degrees cooling, the coolant's temperature settles on +1 degree.

The heat transfer efficiency of 40`60L of water volume is very good and the highest recorded cooling data is 21.5 degrees.

The pressure loss is quite small and it contributes to a certain oil supply.

Furthermore, the radiator water temperature is stable and the volume inside the radiator has reserve of capacity.

The enginefs oil is being cooled, but it isnft connected to the immediate overcapacity.

If the coolant seems to be overheated, it means that there is a problem with the cooling efficiency.

It is not easy to install a cooler core of this size into the narrow engine space. We have to follow the upper hosefs limitations.

Squeezing it into the lower hose after the cooling might cause that the temperature of the coolant returning to the engine is going to raise, thatfs why we installed it into the upper hose.

However, the upper hosefs outside diameter is just a 30mm. It is an eSf letter shaped hose.

We bend the hose coming out of the thermo housing 90degrees and drop it directly below.

At the bottom we turn it into aeUf shape and at just at that point we install the water cooling coil.

The bottom stay's shape differs in the case of NA8 and NB8.

Left: for NA8

Right: for NB8

The stabilizer is being fixed by the bush bracketfs bolts.

To the hose we set up an air extracting plug. We use it when extracting air from the radiatorfs water. Moreover, the pitch is 1/8PT, thatfs why it is possible to install a sensor for the electronic water temperature meter.

In the case of the oil block the aluminum billet is treated with alumite.

We make efforts to reach a light design.

We install it to the oil cartridge in efsandwich-styleff.

We set up two plugs and the 1/8 PTfs water temperature and oil temperature sensorfs installation becomes possible.

We use Mazdafs oil cartridge.

The intake manifoldfs genuine stay has to be cut in order to avoid interference.

The line is AN10 size and it secures sufficient oil volume.

On the market we can find AN8 cooler kits too, though there are some fine differences.

For fitting we use forged type, which is strong and expensive and makes the line solid.

Furthermore, we have to underline the linefs length.

The two In-Out (Collect-Return) lines are extremely short - only 60cm.

In the case of air cooling installed in front of the radiator, the length of the line becomes 2m.

The winding and the long line might affect the oil supplyfs pressure drop.

The silicon hose from SFS comes in the colors RED and BLUE.

We divide the radiatorfs upper hose into two and build in the cooler in between.

It is a setup using the narrow space.

In the case of the hosefs part for insertion we used a stainless band.

It is not a type where there is a hole in the bandfs center. We only set up a ditch and we use a European style one that can stabilize the torque.

In some of the silicone hoses we set up an air extracting plug.

This part is being plugged up by an 1/8 stainless plug but it is also possible to install an electronic water temperature sensor.

During these years Maruha has been developing the water cooled oil cooler.

Its efficiency is good and its price reaches that of racing unit items.

For example, this aluminum adapter is the product of accurate machining.

Not only the designing is difficult, but the NC machining costs are quite high too.

It is a product which costs a lot of time and money.

For many years we have been thinking of preparing a high efficiency cooler kit for our customers.

The price might seem high but if you get to know the details better, you might even think, that it is quite reasonable.

There is a possibility of buying only the lower hose.