The typical trouble is the deformation of rod bearings.

Inside an engine, the parts have to work under strict conditions would be RODS.

Tuning for hi-rev and soup up bring on any stress and it attack to connecting

rods directly.

Sometime they are bended or snapped. These big trouble lead to an engine broken.

Yes, Rods trouble is the most severe case, we have to care about rod's

performance so much when assemble an expensive tuning engine.

The low performance of rods leads to the damage to metal bearings.

There are two types of bearings.

It is for rods and another is for main journals

And the bearing have to function under the more sever condition is for

connecting rods.

When we assemble an engine, anytime take care of a crankshaft with revised bends and lapping of journals, confirm metal bearing clearance, check oil pressure, try reducing piston friction. Any engines have to be assembled with these greatest attentions.

However, with more high rpm and more power up, one thing comes out in spite

of attentions.

The typical trouble is the deformation of rod bearings.

With going up and down at high engine speed, a pure circle of a big end is becoming oval, an elliptical big end give big damage to metal bearings.

Oil clearance between metal bearings and crank journals extinct by elliptical

big ends, and happen metal bearing troubles.

And that opening between bearing back plate and big end inside of rods occur by

deformation, oil flow into these openings and vibration brings corrosion.

Metal bearing receive damages from both side by close in phenomenon.

We can say that high performance rods are absolutely necessary on engine tuning.

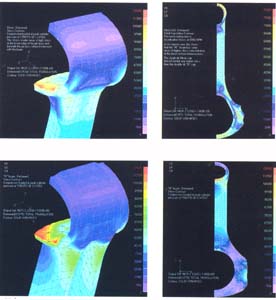

Because this rod is analyzed by engineers (with FEM) with very suitable each

dimensions.

For example, a neck width was calculated on every 1mm modification, light weight

and strength both factors meet on a good balance.

We never say about only light weight. There is something difficulty at

balancing.

Maruha Power Rods have light weight of approximately 100g than stock rods.

However

We had so much effort to reduce only 1g.

Strong bolts for heavy duty and round shape at the shoulder part.

The greatest bolts manufactures / ARP Inc. Maruha Power rods are with their

bolts.

And not just using their bolts, we are adapting large OD bolts than other rods.

These ARP bolts are waist type, can control the correct extension stress.

Regarding on cap meet at big end, very complicated machining process

performed to keep balance between weight and strength.

Also shoulder, side,

bottom, neck, every part is designed by suitable width and thickness.

End cap is fixed by bolt ( not nut like stocks), shoulder part has very smooth appearance which is very effective for strength.

To fix cap position, nock pins are installed. Then you can lock caps very

correctly.

This correct and tough fixing is strong against vibration and improves metal

bearings steady.

Stress at DC (Dead Center)

Running on until high rpm at once. A dynamic engine like this is very fascinating.

Bore size, stroke, metal width, compression, IG timing, Engine power, these

factors give many affection to metal bearings.

But, we have to consider about

more severe point for rods, it is rods stress at a moment of exhaust dead

center.

In case of BP engine (1800cc), assumed piston weight as 400g with over

9,000rpm.

This is our base of a design for rods.

Please think about the situation at DC.

Exhaust DC means that after burning in a chamber, piston go down so fast and continues going up keeping so fast speed to max upper point.

If it is intake DC, compression like brake can reduce piston speed. Though no

brake in case of exhaust DC, piston wants to go through up a cylinder head and

pull out a rod from a crankshaft by so strong inertia.

On the other, a

crankshaft wants to pull a piston down forcibly.

That is a strict moment at exhaust DC.

Heavy piston, high-rpm, more power, these affect rods stress as huge load, born

out close in phenomenon.

Maruha Power Rods are designed against rod stress up to a couple of tons by

using FEM analyze.

Small end.

Small end has full floating process with bush for high engine speed.

ID of small end is the same size as stock rods, any pistons for Miata with

base pin size

can be available for our rods.

There is a taper oil hole at the top to help the smooth by dropping

lubricants.

Weight balance

Always whole weight is measured. But Maruha is checking at each end weight.

This

precision machining is the feature of Maruha Power Rods.

Usually mechanic adjust only the whole weight, if you want more hi-level

technique, have to think about each end weight in details.

Because big end catch up crank journal and small end connect to piston pin.

Thus

from a view point of inertia, rods work separately from big end and small end.

Therefore weight balance on each end is important.