Maruha has started the official sale of its air conditioner kit.

At the time of purchase please provide us with the following information:

A different coolant is being used for NA6 and NA8, however they are similar and for this reason the carryover is possible. It is very convenient to change the coolant to R134a.

However, the NA8 air conditioner kit’s production has been discontinued. It is possible to purchase the necessary supplementary parts but the cost would be too high.

For this reason it is more effective to use a kit when carrying out the exchange.

There are many differences between NA and NB and for this reason it is not easy to carry over the A/C kit.

Maruha made unique improvements and that's why it can be used for NA without any problems.

The full kit provides the possibility of a complete maintenance.

By only exchanging some parts, you cannot make sure that the A/C will work properly for a long time.

The dirt and dust etc. inside the pipe, the condenser and the chamber unit might cause gas leaking.

Gas leaking is not the only reason for the A/C problems. There are others like clogging or the deterioration of the parts.

Especially the NA compressor troubles are frequent.

For this reason using our kit to the exchange is a very good solution.

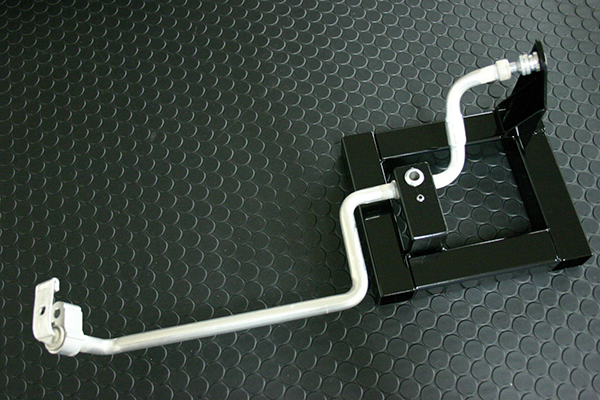

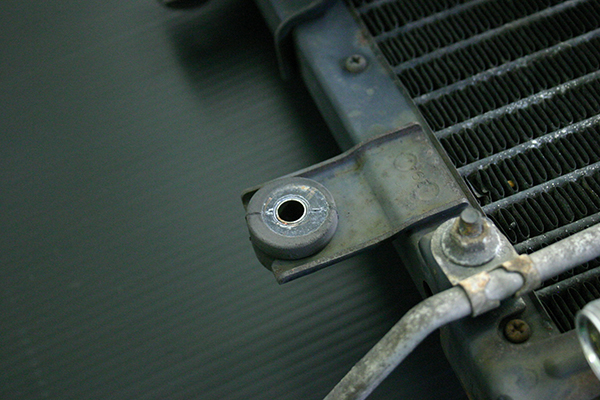

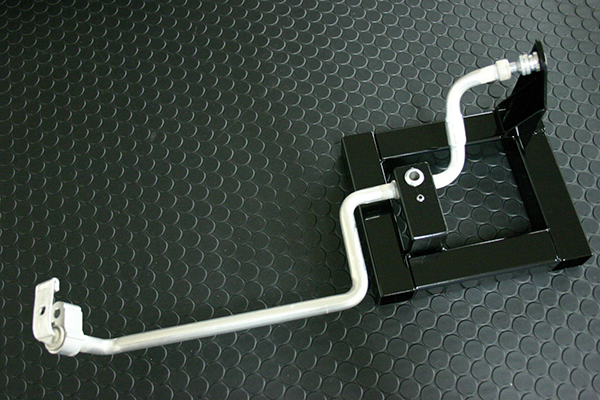

2. Special bracketNA

NB

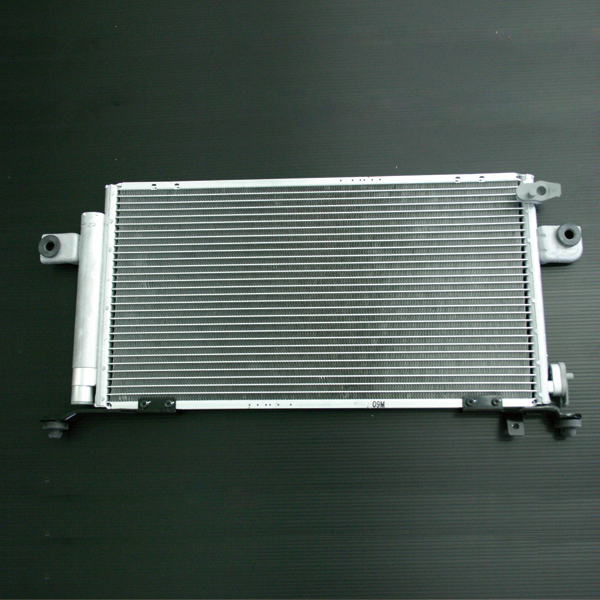

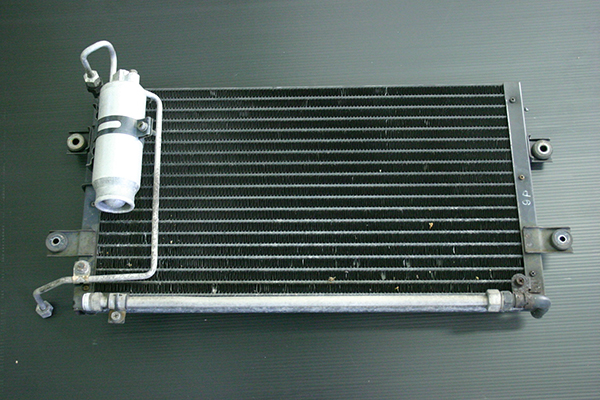

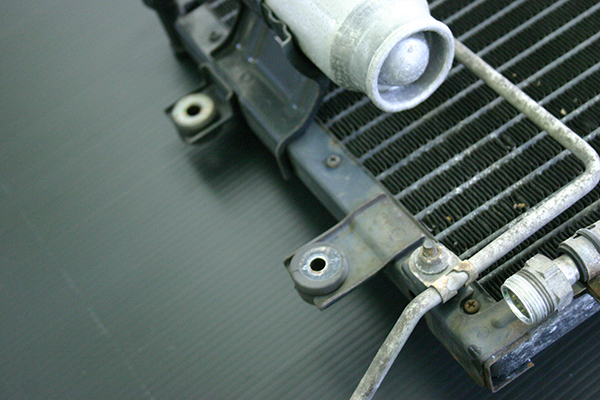

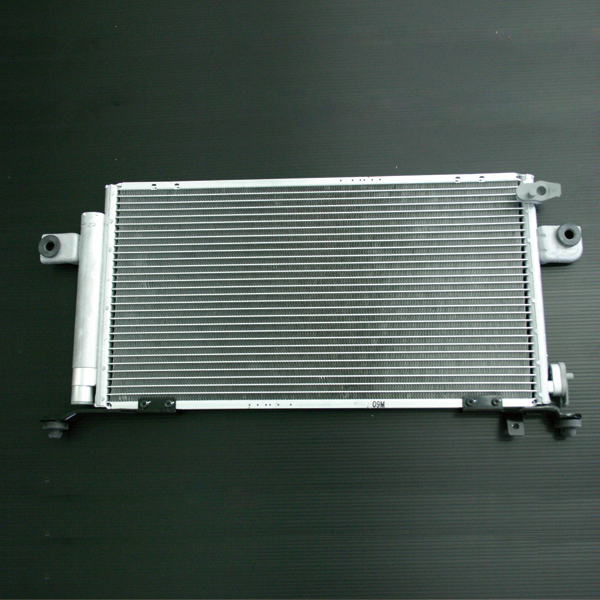

The condenser that is set up in front of the radiator is meant to cool the coolant gas.

The shape of the fitting stay is different in both cases, NA and NB. This problem can be sold with setting up a special bracket.

It is very important to fix it properly.

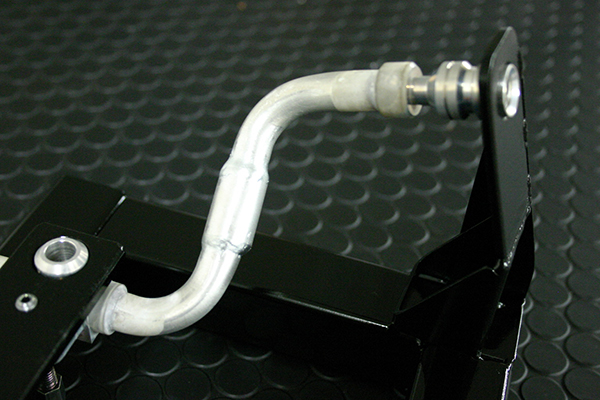

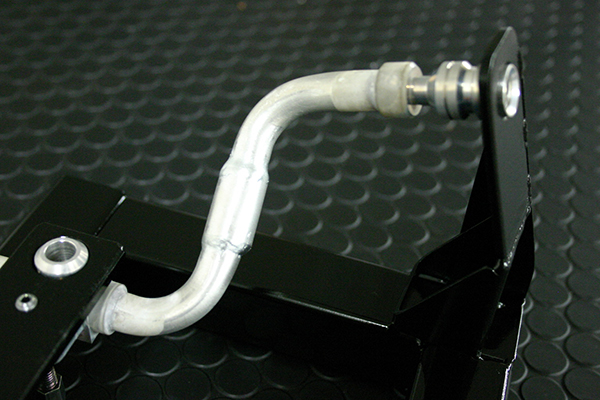

The layout of the pipes is also very different.

For this reason we changed the shape of the high pressure pipe used for gas filling.

We used a special jig for the processing of the pipe.

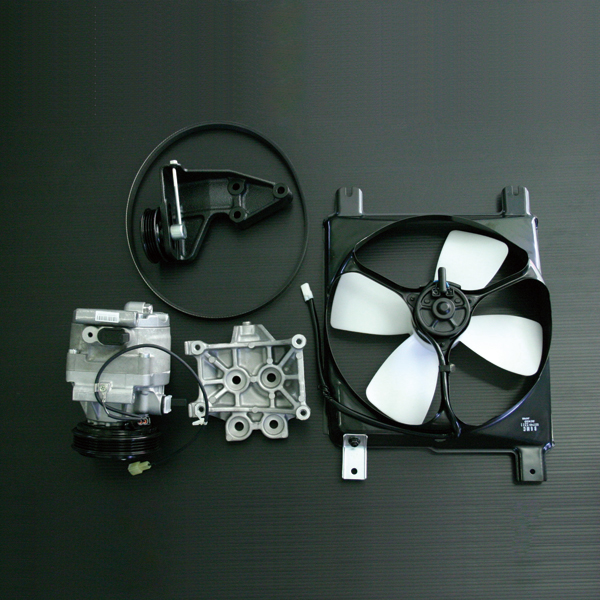

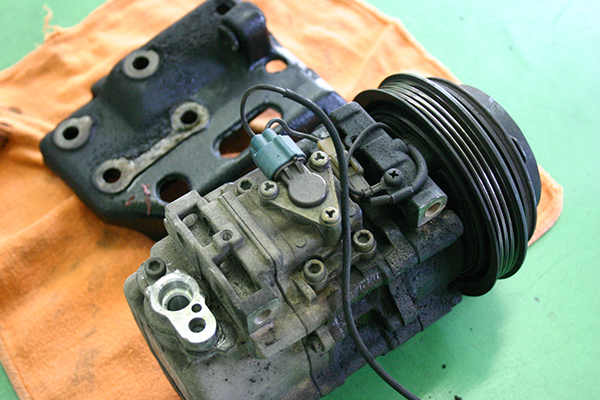

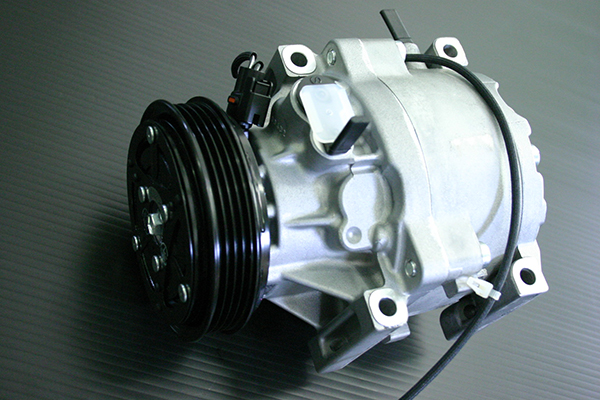

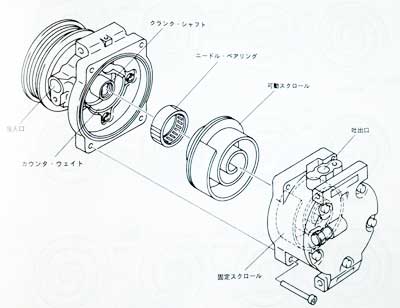

4. Small sized compressor

The merit of the NB air conditioner is its high efficiency.

The light-weight and small sized highly efficient compressor adds another merit to the NB A/C’s carryover.

In the case of the compressor with little resistance there is not too much load on the engine and this leads to a better fuel efficiency.

We have to note that out of the A/C parts the compressor is the one that causes the most trouble. For this reason, it is an advantage to install the highly efficient small sized compressor.

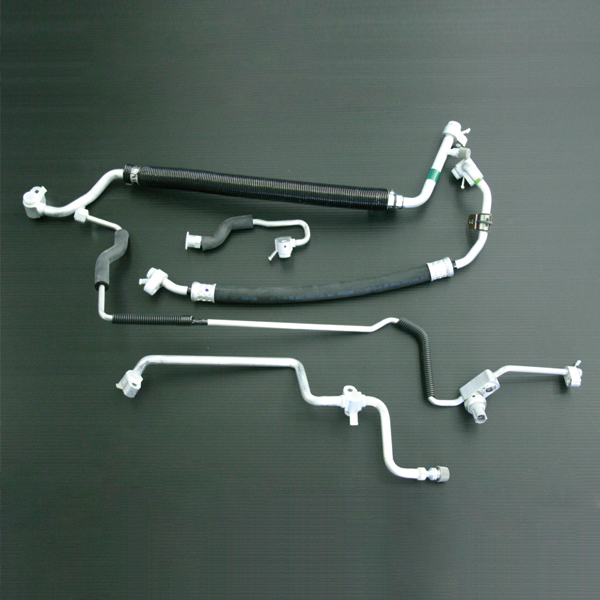

A big difference between NA and NB is the piping’s position.

The bulk head has to be adjusted to the NB piping and an elliptically shaped hole has to be made.

The positioning has to be carried out very prudently.

In Maruha’s A/C kit we use a special pattern paper. Using this pattern, the positioning becomes easy.

Needless to say that making the hole is a difficult procedure and has to be carried out very precisely. Our pattern paper allows you to proceed safely.

We also added the indoor unit to the kit parts.

There are some differences in the case of the NB unit and for this reason some modifications are necessary.

Blower motor → A/C unit → Heater unit

The air is being circulated in this order but their mutual position has to be decided. For this we need a special spacer.

The wiring is in the back of the indoor unit (red arrow). To preserve the wiring space we use the spacer.

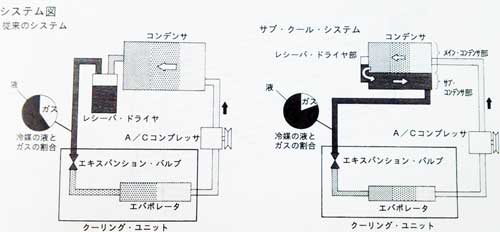

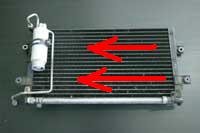

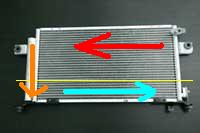

Receiver drier, main condenser, sub-condenser – we use a multi-flow condenser and achieve a better cooling efficiency.

Left: the NA condenser has only one layer and for this reason compared to NB, the cooling effect is worse

Right: the NB condenser has two layers, the cooling happens in two steps

By using a scroll-type compressor, we decrease the engine’s load which leads to a better fuel efficiency and less noise.

By using the sub-cooling system we aim for a small, compact size.

Please contact us for further information.

[home]