For a long time we have been selling only genuine rotors, however this time we would like to introduce our new original brake rotor.

Just like the pads, the rotor too is a part that wears out. The condition of the abrasion differs depending on the length and way of usage but basically it is supposed to be exchanged periodically.

When we were developing our brake rotor, we kept in mind many things. For example:

1. If it is a part that anyway wears out, couldn’t we provide it for a more reasonable price?

2. We want to develop a high performance strengthened rotor.

At Maruha we don’t do second processing of the rotor base as it is being done in the case of genuine rotors.

The material we use is cast iron, but with our technique it becomes strong against heat change.

The machining precision is high – distortion and balance are secured. For a good antirust effect we use special paint.

During normal conditions we can secure long durability, however driving on circuits or sharp operation might cause some kind of small change or judder.

The rotor is generally a part, which wears out, gets abraded, that’s why we cannot take any claims. After the installation please consider the relation between the rotor and the pad and try to drive in a way that makes it easier for the rotor and the pads to run in.

The high performance rotor (PFM) is a highly efficient rotor. Its base is the STD rotor with simultaneous heat treatment and slit processing.

The heat treatment is somewhat near annealing but still different and the hardness improves by 15 to 20%.

The merit of heat treatment is the safety (during high temperature and improving of surface hardness (durability).

After the treatment to make the precision (planarization) better we carry out surface scrubbing. During this surface scrubbing we actually measure the rotor’s precision.

The difference between the rotor’s cold and hot temperature is very big and the extreme repetition of expansion and contraction leads to distortion or crack.

The heat treatment stabilizes the systematic components in advance and it can correspond to this big difference in temperature, so that it cannot be damaged easily. However, in any way the rotor wears out and abrades, so we cannot take any claims after the installation.

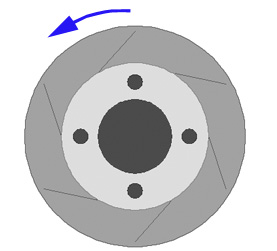

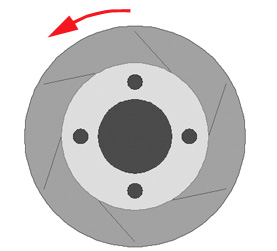

Slit processing is a very important processing method for braking performance. By the slit’s number, shape, direction of rotation etc. the efficiency changes.

At Maruha we consider as a basis normal driving circumstances and so we set the slits’ number to 6. More slits promote quick abrasion, but this way we can eliminate even the abnormal noises.

Regarding the rotation direction, we have to mention that there is no standard for positive and negative rotation. Any rotation direction is o.k.

We recommend this setup to users who usually drive under normal circumstances mainly on the streets.

We recommend it to users who like winding drive and driving on circuits, who don’t worry about the pads’ abrasion and noise and are interested in braking performance.

Make sure that the rotation directions match.

After you have already started using the rotor, don’t change the direction.

The braking performance has to be controlled strictly.

Wrong or extreme ways of usage will reduce the safety of the rotor.

The performance and safety are widely influenced by the maintenance and the way one uses it.

[home]