Maruha’s original program is being sold separately.

Maruha’s original program is being sold separately.

These three points make a set. However the actual procedure is not easy.

You might think that an engine, harness and ECU can be put together just like that. But in reality it is not as easy as it seems.

Even if you swap these three things, how is the essence of the tuning?

If the ECU is genuine, its extent will be limited.

What's Maruha's solution?

How would you like that?

Maruha’s BP-VE swap is a very smart swapping method.

We do reliable tests on our engine bench.

Let’s take a closer look.

The abbreviation VVT is generally used on the market, so let’s use it on this webpage too.

Nowadays’ cars’ VVT function is already a universal function and even the light vehicles are equipped with it. Furthermore, both the intake and exhaust sides of advanced engines have VVT function. Though, its control is very complicated.

The genuine piston used after NB8 (Sr-2) is a high compression piston with the highest compression ratio in between the Miata’s (Mx-5) NA・NB models.

The compression ratio can reach 10.5:1.

By the way, the compression ratio of the BP engine used for NA8 is 9.0:1.

The valve timing is being controlled hydraulically by the VVT. In fact, even the camshaft’s profile itself varies a lot.

On the intake side the lift reaches the genuine value – 9.8mm and forms a sufficiently high lift cam.

In the case of the BP engine the crankshaft is fixed in the engine block using only 5 main caps.

In the case of the engines of other companies the main cap is built-in in a ladder beam style. Our company doesn’t aim for such a high performance when talking about Miata/Mx-5 engines.

However, starting from NB8 (Sr-2) this main cap is being connected using a solid baffle plate and this improves its hardness.

The VVT function of the NB8 (Sr-2) is being controlled hydraulically and more oil is needed than in the case of NA8 or NB8 (early model).

That’s why starting with the NB8 (Sr-2) models an exclusive oil pump is used.

From the outside the pump looks the same as before, but the trochoid in its inside has become slightly thick and it is designed as a high flow pump.

The shim’s high pressure used to the spring of the relief valve makes the oil pressure of the high RPM higher. However, because of the high flow caused by the thick trochoid the quantity of the oil rises.

It is possible to lubricate enough oil to each part even from the low RPM areas and to get stable oil control.

Take a look at the performance curve below

It is the performance graph of the BP engine measured at our company’s facility.

Already in the case of B's (NB8 Sr-2) simple swap we can reach a considerable power up.

However in the case of C which is the model without air flow meter (Freedom control) it is possible to show the efficiency even more.

The VVT function conducts wide engine management, for example the torque up in the low-speed areas, the growth in the high revolution areas and shows the BP-VE unit’s engine efficiency even more.

Let’s take a closer look at the VVT function.

We at Maruha manufacture and sell original slide cam pullyes, but these are for the adjustment of the valve depression time caused by the camshaft.

The duration and the lift turn into the cam’s efficiency itself. That’s why the cam pulley doesn’t adjust this duration and the lift.

The cam and the crankshaft operate together through the timing belt – at the same time the crankshaft rotates two times and the camshaft rotates once.

The crankshaft’s rotation equals the piston’s vertical motion. This means that merged with the fluctuation of the piston, the opening and closing of the valve happens inside the cam.

With the piston’s position the opening and closing time of the valve (timing) is altered and this alteration is the role of the slide cam pulley.

However, even the slide pulley’s position is fixed at one place and even if we talk about the valve timing of low RPM or the lengthening of high RPM timing, they cannot be changed unless the slide pulley is readjusted after the fixation.

That’s why many people thought: "How about using an oil controlling adjustable pulley to this valve timing?" The result of this thought lies in the VVT function of the models after NB8 (Sr-2).

The method used in Honda’s VTEC, Toyota’s 2ZZ etc. is the super complex function of duration and lift control. On the market there are camshafts called tuning camshafts, but the function of which doesn’t exceed that of the genuine camshaft.

This proves how difficult it is to control the cam’s surroundings.

The adjustment of valve timing by slide pulley is called ignition lag and advanced ignition.

Here we will not go into their deep explanation. Let us just say that the engine specifications and the camspec‘s timing are generally decided by them.

However, the VVT function controls the ignition lag and the advanced ignition combined with many different movements.

In this way the VVT function merges the ignition lag’s and advanced ignition’s merit and cancels their demerit.

Everyone thought that using BP-VE swap with the car's original harness is not possible. But by using Freedom control (developed with the help of the company E&E) together with the relay harness we managed it.

For example, in the case of NA8 we can detect the cam position (piston position) by the crank angle sensor at the cam’s tail. However, in the case of NB8 (Sr-2) we can detect the piston’s position by projecting a plate to the crank pulley.

Moreover, we can detect the cam position from the cam tail’s projection.

Furthermore, the ignition system becomes direct ignition coil and the VVT that didn’t originally exist in NA8 has to be controlled.

The meaning of the functions realized by Freedom control is very deep and even from the tuning’s viewpoint it is a big progress.

The air flow meter used for NB suppresses the air resistance using a hot wire, but in reality that air flow is not just a pipe. The inside is a mesh structure and we can easily imagine its big effect on the air resistance.

Cleaner box for NA8

Cleaner box for NA8

Cleaner box for NB8

Cleaner box for NB8

The meaning of removing the genuie air flow meter is that the intake side’s parts and its layout can be widely changed.

The parts with air resistance can be omitted and the engine’s original efficiency can be improved by MAP. As you can see, the meaning of "Freedom change" is extremely wide.

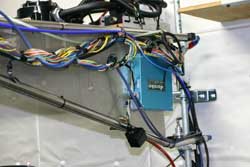

The car harness and each sensor of the BP-VE is being connected using Maruha’s original relay harness kit.

However, an intake air temperature sensor for Freedom control (primarily not used as genuine) and the vacuum sensor’s wire processing becomes necessary.

Moreover, if using BP-VE manifold, the rearrangement of the terminal for the sensor of the TPS (throttle), the ISCV (idle) etc. has to be done.

However, each of the couplers and terminals can be found in the kit, that’s why the wire processing is possible at any garage.

If you already owe a Freedom ECU, it is possible to upgrade it.

Those that can be upgraded can be distinguished by the label that is pasted on the Freedom itself. Please contact us for further information.

There is a possibility that an old version of Freedom cannot be upgraded.

Many NA8 owners might be satisfied with a simple BP-VE swap but still want to try to change to Freedom. You can also check out Maruha’s F-cam standard fine tuning.

Maruha’s F-cam launched after thoroughly repeated bench tests and actual performance proofs can certainly improve the BP-VE engine’s efficiency.

For further information see the page about F-cam for VVT.

It is good to find a cheap used engine and swap it, right?

The cost is an extremely important factor.

However, the used engine has its own risks.

In what way was it used?

How is its mileage?

Was the engine oil changed regularly?

Was it removed from the car for a long period of time? Is the internal rust O.K.?

What would you do if after equipping it a defect was detected in the inside of the engine?

There is no end of these kinds of worries.

In that case, how about an overhaul in advance?

The engine O/H is Maruha’s true value.

Mahle’s forged piston is our recommendation.

Mahle is the world’s greatest piston manufacturer.

It is the piston supplier of Ferrari, Porsche, high-class European cars and F1 racing cars too.

The 83mm sized can be equipped with only honing, but if aiming for torque and power, we recommend the 85.5mm one.

The H-beam conrod is very effective too.

There is the method of using a new engine instead of an old one.

In the case of a new engine, from the cam cover through the oil pan, everything is new.

A secure engine swap becomes possible.

By O/H conducted while paying attention to abrasion and the used up parts, the engine can be refreshed.

By replacing the F-cam and piston in this NEW engine, it is possible to build it up to a Maruha engine.

[Home]